Case Bezel Machining, Dial Printing and Hand Fitting

Here, I’m going to write about our work with a vintage, 18K gold Breitling chronograph. Is has a few problems: the bezel is missing, the dial is tarnished and stained, and both seconds hands are also missing.

As is, do you think it has the potential to become a beautiful and beloved timepiece?

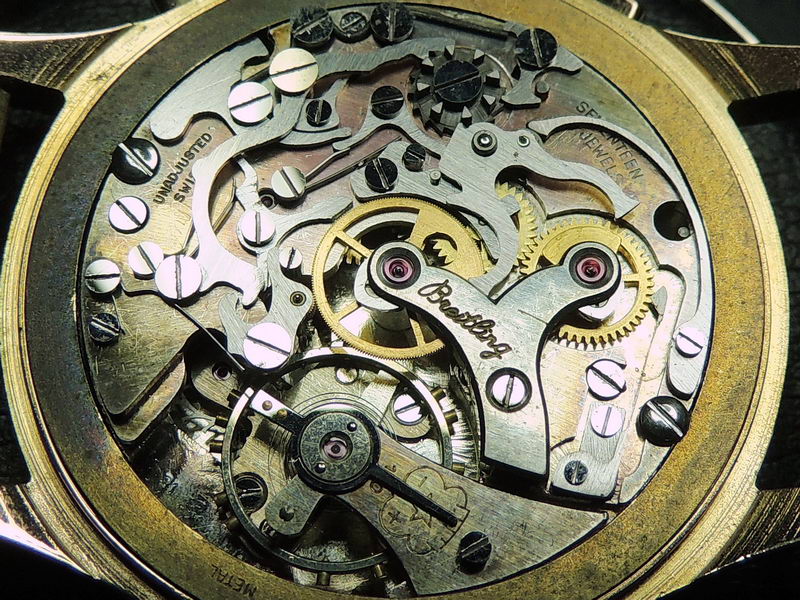

The movement can be identified by its 45-minute chronograph counter positioned at “12” (pictured above).

It’s famous Venus 170 caliber (below).

The Venus logo is visible on the balance cock.

For this project we fully stripped down and serviced the movement, but in this review we will focus more on the complex problems, such as the dial and case restoration.

New Bezel Machining

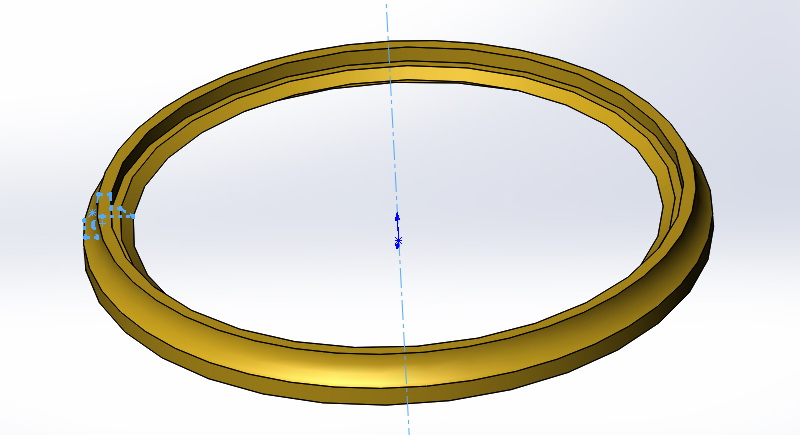

First of all, we create a model of the front bezel, based on actual case sizes.

A more detailed review of the case and bezel making process can be found in our Ulysse Nardin 14K gold making project.

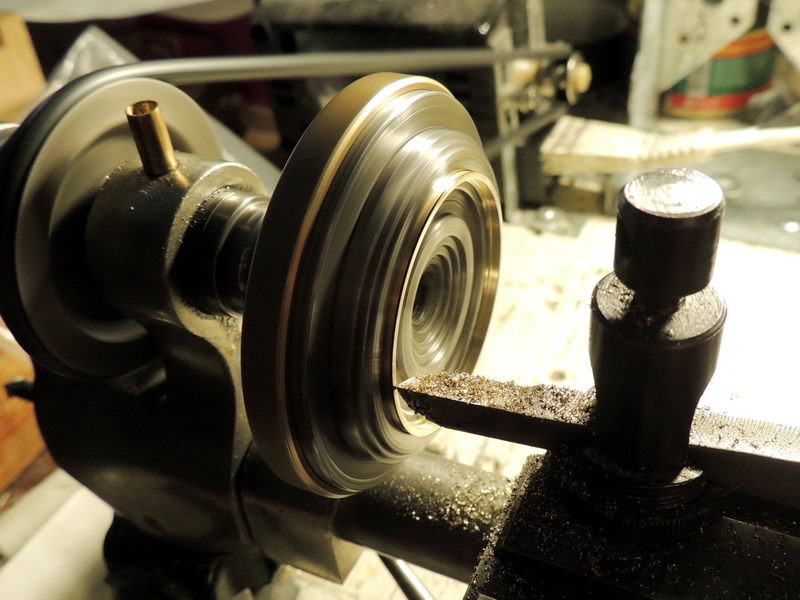

The metal blank is then machined in 0,005 – 0,10 mm tolerances, and with numerous fitting checks to the actual case to ensure that it fits properly.

The next step is crystal mounting and hands fitting. Fitting the hands is not quite as easy as you’d think, as we have to use hands that are roughly the same age and style as the rest of the watch, using original vintage spares only, not new.

All fitted hands must strictly comply with three parameters:

- Size

- Style

- Deep blue tone

Breitling Chronograph Dial Printing

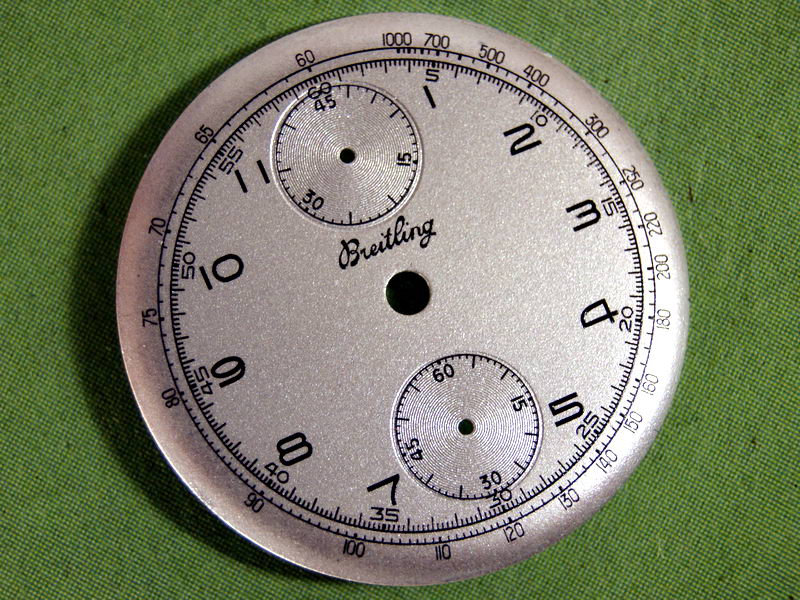

The stains and tarnish on the dial are not really dust, but actually a corrosion in the lacquer layer. To get rid of this damage we will have to strip off all the remaining paint, and then make a new print on the original plate.

Typical stages of dial restoration:

- Original dial scanning, retouching where needed

- Precise computer modelling of dial layout – lines, numerals, indices, signatures

- Creating a typographic matrix for each printing layer

- Stripping off the dial plate and cleaning it down to the naked metal

- New galvanic base layer – gold/silver plating

- Printing all layers of the dial, and then drying

- Protection varnish

After the dial is ready, we will mount it and make some final adjustments.

Of course, any original dial is much more of a collectible item than a restored dial. We reprint the dials only in case of really significant damage, and never recommend renewing the dial in basic restoration cases.

If you have any questions, feel free to contact us via e-mail horological.underground@gmail.com , or via our Contacts page. Our shop is based in Bristol, United Kingdom.